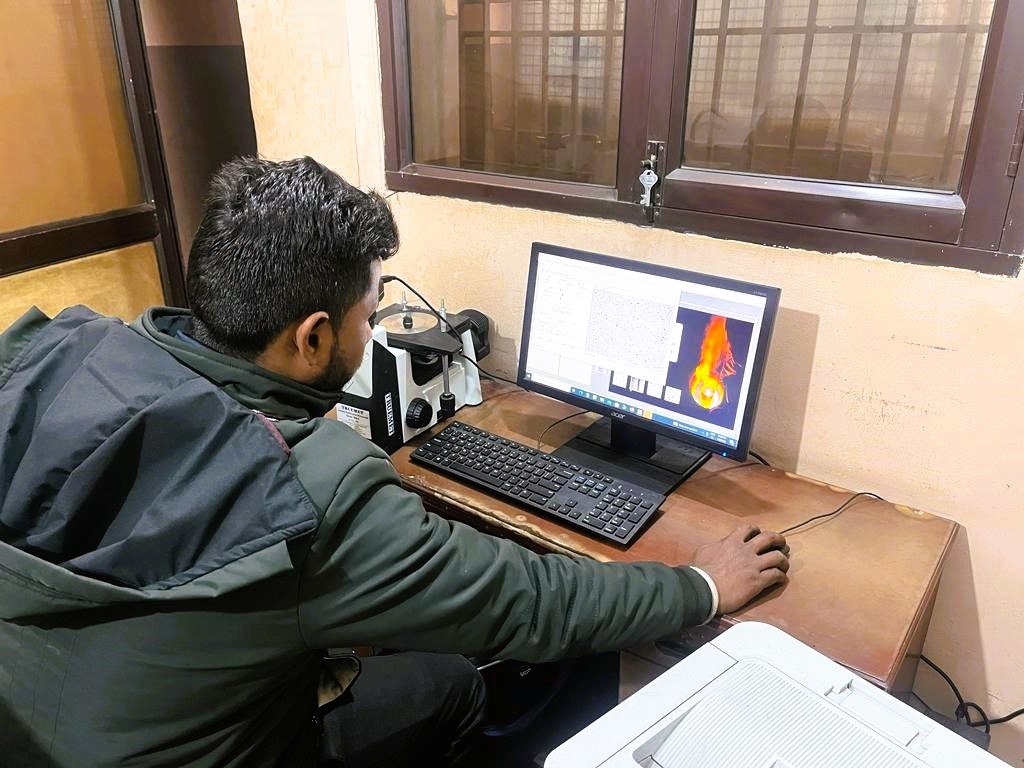

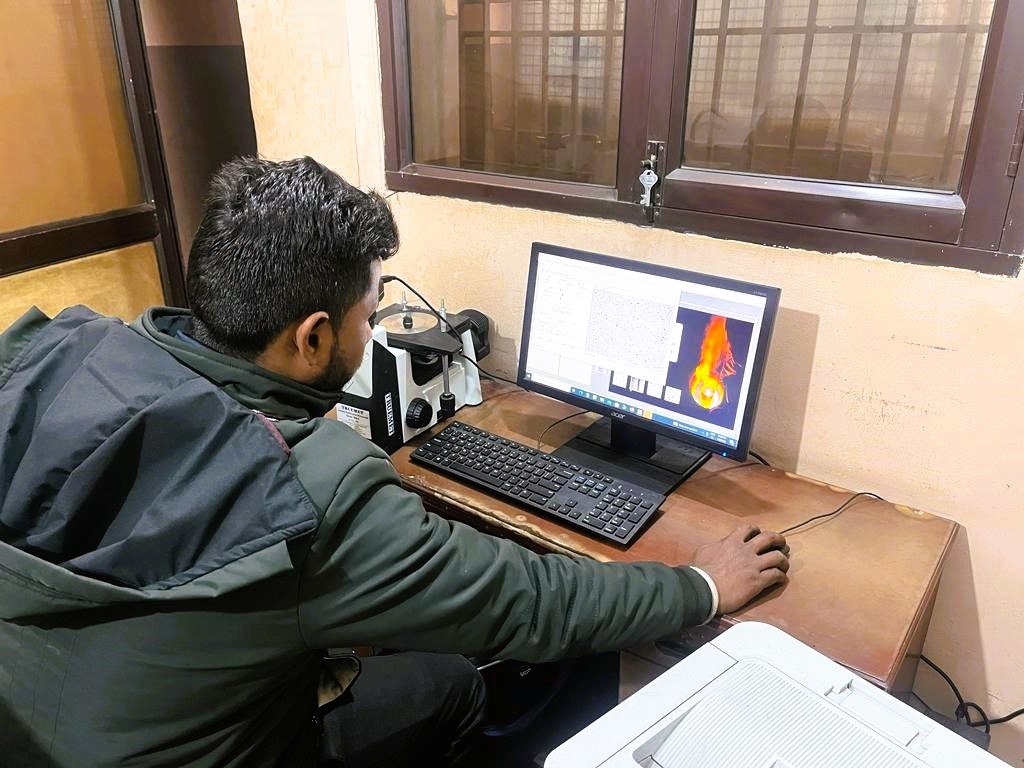

Micro-Hardness Testing Lab

Manufactured metal parts aren't ready for use right out of the mould. They often need a coat of paint, powder coating, or welding work. But before this can happen, the surface of the metal part must be clean.

Shell Moulding prepares metal parts for further processing like painting or powder coating. This step is necessary to ensure the coat adheres properly to the part. Shot blasting can clean off contaminants like dirt or oil, remove metal oxides like rust or mill scale, or deburr the surface to make it smooth.

Furnaces are devices that generate heat in a controlled manner through the combustion of a fuel source. The thermal energy is then used to heat spaces such as rooms, buildings, or other structures. Other furnaces may be used in commercial and industrial settings for the processing of materials.

a coil carrying alternating electric current surrounds the container or chamber of metal. Eddy currents are induced in the metal (charge), the circulation of these currents producing extremely high temperatures for melting the metals and for making alloys of exact composition.

The machine table travels upward to squeeze the sand between the pattern plate and a stationary squeeze head. The squeeze head enters into the sand frame and compacts the sand so that it is level with the edge of the flask. These machines rammed the sand harder at the back of the mould and softer on the pattern face. Squeezer machines are very useful for shallow patterns.

It has been developing and manufacturing machines for grinding, satin finishing, deburring, and finishing of sheet metal. Pursuing as the founding value of its production the attention to the quality of the 100% Italian material, over the years it has been able to become a reference production reality for the sector. The highly qualified staff allows a constant development of the production for the primary objective of satisfying the customer needs.

Two Station with Linear Trasfer Machine * Auto Loading & Unloading of Roller. * Hole Present Confirmation. * 1st Station Job Singling Unit. * 2nd Station Drilling & Chamfering on One Side. * 3rd Station Chamfering On 2nd Side. * 4th Station Checking of Hole Presnt on the Job & Unloading of the Job in the Chute

Copyright © 2022 Garg Techno Cast All Rights Reserved || Designed By

kite Infotech

kite Infotech